It’s impossible not to marvel at what CAD and CAM technology has done to jewelry making. Jewelers have transcended from designing on paper and manufacturing by hand to designing on computer and manufacturing by cutting-edge machines.

In this blog, we will explore the CAD and CAM jewelry modeling world, highlighting how they have transformed the jewelry production process.

Basics on Jewelry CAD Modeling

CAD, which stands for Computer-Aided Design, is the process of creating digital representations of jewelry pieces through specialized 2D and 3D modeling software. It serves as a guide for manufacturing, allowing designers to create a jewelry cast that includes every detail of the piece from the placement of gemstones to the perfection of filigree work.

Jewelry in 2D

Involves creating flat, two-dimensional representations of jewelry pieces. It’s used for planning and visualizing the basic layout of the jewelry to communicate with manufacturers or get clients’ approval properly.

Jewelry in 3D

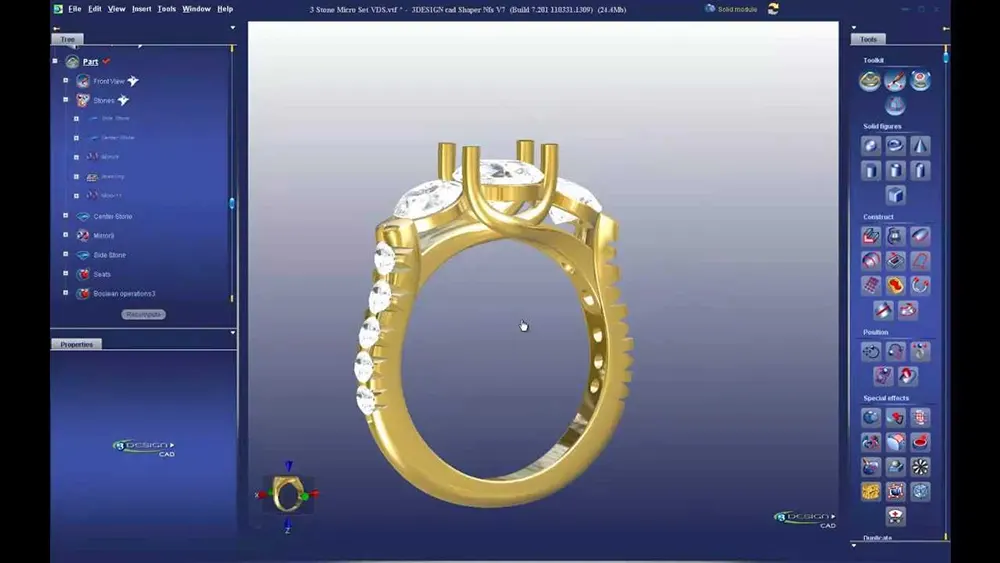

3D jewelry design involves creating fully realized, three-dimensional digital representations of jewelry pieces. 3D CAD jewelry offers a comprehensive visual of the jewelry design from all angles, prompting the detection and correction of errors before production starts.

Popular CAD Modeling Software

There are some software used for creating jewelry CAD files. Some of the popular ones are AutoCAD, Autodesk, Inventor, CATIA, and Solid Works.

Basics on Jewelry CAM Processing

CAM, which stands for Computer-Aided Modeling, is the use of software to create CAD representations. It involves generating a prototype of the final jewelry piece.

CAM processing helps to guide the manufacturing process. It allows jewelers to properly interpret intricate designs into precise, high-quality pieces.

Popular CAM Processing Software

There are many types of software used for CAM processing. Amongst them are Work NC, Siemens NX, Power MILL, and SolidCAM.

Is CAM a Must?

NO. CAM is not necessary for the making of all types of jewelry.

CAM is ONLY essential for jewelry that needs CNC (Computer Numerical Control) machining, that is, pieces that require specialized tools or lasers for accurate production. But, if the jewelry is made by traditional methods like casting, lost wax casting, hand fabrication, or electroforming, CAM is not needed.

On the other hand, creating digital representations through CAD modeling is essential for making all types of jewelry regardless of the manufacturing method.

CAD vs CAM in Jewelry: What’s the Difference?

CAD and CAM are technologies used for designing jewelry via computer software, but they are largely different.

| CAD | CAM | |

| Full Form | CAD refers to Computer-Aided Design. | CAM refers to Computer-Aided Manufacturing/Modeling. |

| Definition | CAD is the use of computers for designing. Computers are used to aid in creating the design, modifying, and analyzing the designing activities. | CAM is the use of computer software to control machine tools in the manufacturing of modules. CAM transforms engineering designs into fully-grown products. |

| Purpose | The purpose of CAD is to make 2D technical drawings and 3D models. | The purpose of CAM is to use 3D models to design machining processes. |

| Main Focus | CAD focuses on the design of a product or part, structure, and colors. How it looks, how it functions. | CAM focuses on how to make the jewelry. CAM adds surface treatment details, texture, and different gemstone rendering effects. |

| Software | AutoCAD, Autodesk Inventor, CATIA, Solid Works | Work NC, Siemens NX, Power MILL, SolidCAM |

| Service Price | More economical | More expensive |

| Final Effect |

From CAD to CAM Processing

The manufacturing of any jewelry begins from CAD. When the design is completed in CAD, it is transferred into CAM.

Steps Involved in the CAD to CAM Process

Here is a typical case study: from sketch to product of how jewelry engineering is done.

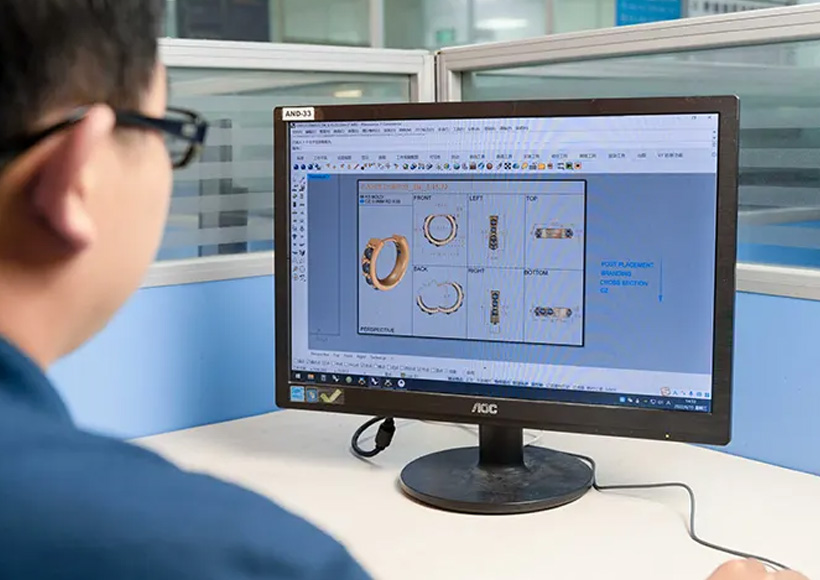

- CAD Model Creation

This step involves designing the jewelry using CAD software. The designer creates a detailed digital model, inputting all specifications, such as dimensions, shapes, and aesthetic details. The model is created to meet the final product’s requirements.

- Export to CAM-Ready Format

Once the CAD model is created, it is exported into a compatible CAM file format (such as STL). All the detailed design information from the CAM software is accurately replicated in the CAM file software.

- Prepare for Manufacturing

The exported CAD model is transferred into the CAM software, where the manufacturing instructions are generated. This step often includes defining machine paths, selecting tool types & sizes, setting speeds, and other manufacturing parameters.

- Execution

Involves sending the instructions generated from the CAM software to the manufacturing machinery, such as the CNC machine or 3D printer, to precisely cut and shape the jewelry material into the desired form.

How Jewelry CAD & CAM Works in Jewelry Manufacturing

This is a breakdown of how CAD and CAM work together in jewelry making, and how the resulting jewelry pieces are processed to their finished state:

- CAD & CAM

The designer uses CAD software to create a detailed, three-dimensional digital drawing of the jewelry. Then, the 3D CAD jewelry model is exported to a compatible CAM file format and transferred to the CAM software (as specified above).

- Jewelry Parts Assembly & Cleaning

After the jewelry has been cast by the production machines, the various parts are assembled to complete the jewelry’s full look. This includes setting gemstones into metal frameworks or attaching different metal components.

Then, the assembled jewelry undergoes thorough cleaning to remove any residue coming from manufacturing, such as wax or machining oils.

- Polishing, Finishing, & Quality Control

Finally, jewelers polish the jewelry to enhance its gleaming as high as possible in the final stage. This involves smoothing the surface, removing scratches, and enhancing the appearance. Finishing touches like plating or engraving can also be added to meet the desired look.

Lastly, jewelers conduct a final strict inspection to ensure the jewelry meets all quality standards and design requirements. This ascertains if the production went smoothly or not.

Benefits of CAD & 3D Rendering for Jewelry Business

The integration of CAD and 3D jewelry mold manufacturing techniques in jewelry production has brought numerous benefits to both jewelry businesses and customers. Some of them are:

For Jewelry Businesses and Brand Owners:

Saving Time and Money

Replacing the traditional hand drawing and cast-making process with digital modeling has shortened production time massively. The advantage of having all the design tools in the CAD and CAM software is that less time is used in every manufacturing step.

These advanced technologies come with a reduction in costs. Jewelers understand the material requirements and technicalities ahead of production, resulting in mass production using reduced materials.

Reducing Product Returns

Through CAD and 3D rendering, jewelry designers can see how the finished piece will look, allowing them to make necessary corrections before production begins. After the final design is created, it will be sent for confirmation and highlighting of potential errors. This minimizes the chance of error that could lead to product returns.

Building Brand Trust and Loyalty

CAD, 3D rendering, and CAM allow accurate jewelry designs, guaranteeing that the final piece meets the initial vision. This precision to detail builds trust with customers as there is assurance that they will receive exactly what was promised.

For Customers:

- Immersive Visualization

Offering customers 3D rendering of the jewelry they want to make allows them to see exactly what the finished piece will look like even before it’s made. The jewelry can be viewed from all angles, with clear visuals of intricate details and how different materials and gemstones will appear. It allows customers to imagine themselves wearing the jewelry.

- Personalization and Customization

CAD and CAM enable personalization and customization, allowing customers to have distinct jewelry pieces designed to their preferences. From unique engravings to custom-made settings of stones, the possibilities of customization are limitless.

- More Confident Purchases

With vivid visualization of the 3D jewelry rendering, customers have a clear picture of how the jewelry will look and if it’s exactly what they desire. This reduces uncertainty and increases confidence in purchases.

How Does Jewelry Rendering Differ from Finished Jewelry?

Jewelry rendering is basically the pictorial view of CAD and CAM designs. Jewelry CAD rendering services showcase how the jewelry will look after casting. But after casting, there are other manufacturing processes like jewelry parts assembly & cleaning, as well as polishing, finishing, & quality control.

Here are points that further explain the difference between jewelry rendering and finished jewelry:

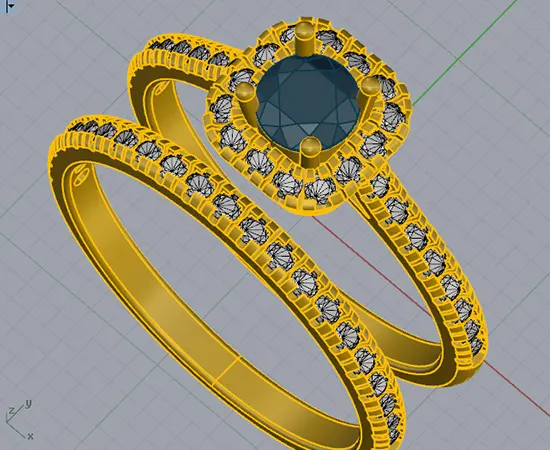

- CAD Drawing

After the CAD drawing is exported and sent to CAM, the designs are transferred to the manufacturing machines for production. The produced jewelry parts have extra metal that has to be removed by hand. Consequently, the prongs look taller with sharper edges and the jewelry appears bigger than the desired piece.

- Texture

The texture of the finished jewelry may be slightly different from what the render says. Hence, this requires additional finishing to achieve the desired feel. Also, the color or brightness of the stone and precious metal displayed by the 3D render may be different from the finished jewelry. In fact, the gemstone’s color may not be true to life, especially non-natural gemstones.

- Claw Setting

3D renders show a relatively high claw. This is intentional because the jeweler has sufficient material to work with when setting the stone. The extra height in the claw setting allows for precise adjustments and ensures the stone is securely and aesthetically set. During the actual setting process, these claws will be meticulously trimmed, shaped, and polished to hold the stone firmly and achieve the desired look.

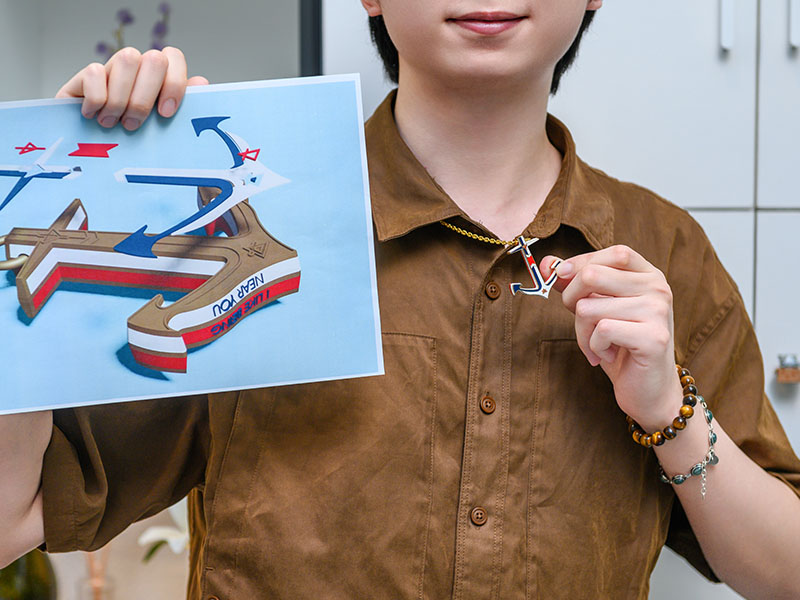

Case Study: Jewelry Rendering vs. Actual Jewelry

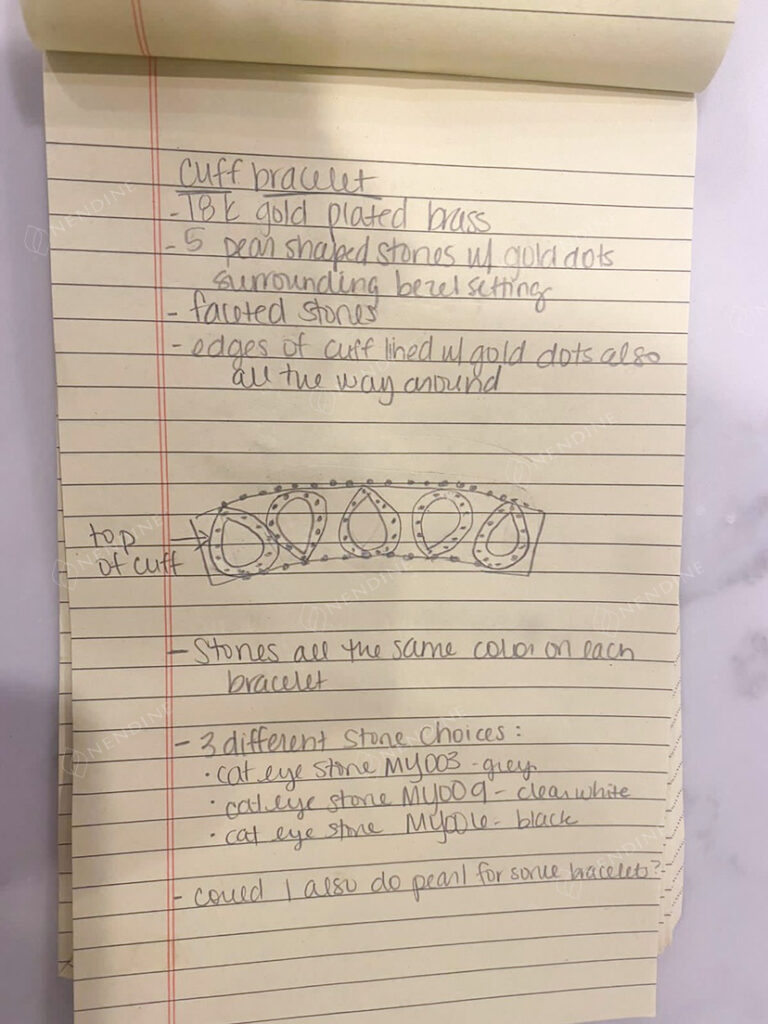

Check out how we help create a gemstone bangle from a piece of simple sketch.

How Do You Start Working with a CAD Designer?

You don’t need to be an expert in the jewelry industry to professionally work with a CAD designer. Simply send a sketch or idea to your CAD designer and you will get the initial 3D model. You can then make demands for the 3D model to be refined further with more specifications.

Looking for a great CAD designer to work with? Nendine is your best jewelry designer. We are a sustainable jewelry manufacturer who provides CAD services custom-made to your preferences. You will enjoy improved customer experience, faster lead time, lower costs, and overall brand advancement when you partner with us.

At Nendine, we bring more than just jewelry CAD rendering services, we grow together with you by offering industry and market insights.

Key Takeaway

CAD and CAM have changed the way designers conceptualize and manufacture jewelry. The powerful combination of these technologies with professional craftsmanship has expanded the scope of ideation and creation of customized, high-quality jewelry pieces.