Gold filled jewelry holds a significant place in the jewelry industry. Known for its lasting luster and shine, it’s popular among customers who want gold’s aesthetic without the huge price tag.

Source: Pinterest

But to achieve high-quality gold filled pieces, jewelry designers must adhere to strict production methods, and ensure that the required standard is met. In this article, we will answer questions like what does gold filled mean, how is gold filled jewelry made, and how can it be identified & tested.

What is Gold Filled Jewelry?

Gold filled jewelry is a description of a thick layer of gold bonded to a base metal (usually brass, copper, or silver), making it a viable option for people who want a replica of solid gold but at a cheaper price. There’s often a comparison between gold filled vs gold plated vs gold vermeil jewelry. However, they are different.

- Gold Filled:

The gold layer applied in gold filled jewelry must be at least 1/20th of the jewelry’s total weight (5% of the jewelry weight). This makes it very durable, retain its luster for a long time, and look more like solid gold.

Source: Pinterest

- Gold Plated: The common thickness most fashion jewelry brands apply is 0.05 microns, which is prone to fading over time, particularly when frequently used.

- Gold Vermeil: The gold layer applied in gold vermeil jewelry must be 2.5 microns thick and is usually plated on sterling silver base. This offers better durability than gold plating, but it still doesn’t last as long as gold filled jewelry.

Source: Pinterest

US Gold Filled Standard

According to the Federal Trade Commission (FTC) Standard, the gold content in the gold filled jewelry must make up at least 5% (1/20th) of the total weight. This ensures consistent quality for all pieces produced and makes sure customers enjoy the benefits of gold filled jewelry for years without complaining of fading or tarnishing.

How is Gold Filled Jewelry Made?

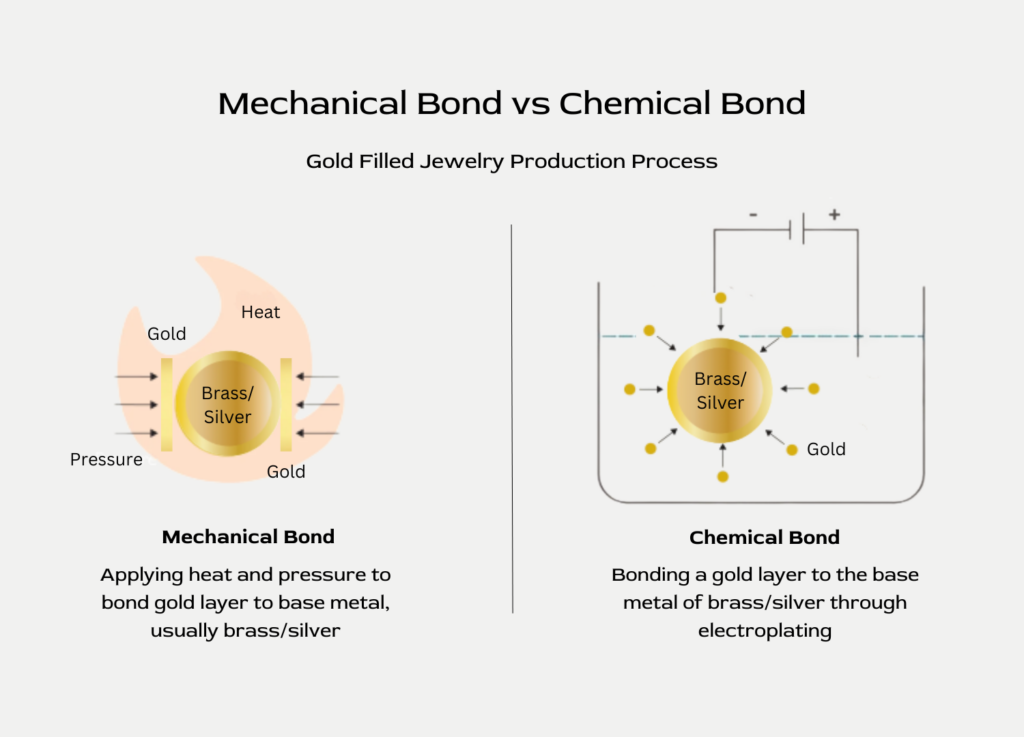

Explained below are the 2 methods of making gold filled jewelry:

Mechanical Bonding

In this method, a thick layer of gold is bonded by the hand or mechanically to the base metal, using a combination of heat and pressure. The gold is applied in layers to make sure it sticks firmly and forms a durable bond with the base metal.

Process Explained

- Cleaning: The base metal should be properly cleaned, as this affects how well the gold layer sticks. If the gold is bonded on a base metal with particles, it will result in unbalanced and uneven surfaces. This may cause the gold to wear off quickly.

- Gold Bonding: A thick sheet of gold is gently layered over the base metal. Then, heat and high pressure are applied to make the gold bond firmly to the base metal.

- Rolling and Shaping: The metal is rolled and drawn into thin sheets or wires of various shapes. The applied gold layer should remain proportional to the base, ensuring that the minimum of 5% gold content is maintained. This further strengthens the bond and makes the gold filled jewelry durable.

Chemical Bonding

In this method, the gold layer is applied using an electroplating process, where the base metal is submerged into a solution containing gold ions. Then, an electric current is applied to the solution, causing the gold to bond with the base metal.

It’s crucial to note that while this method may use a similar electroplating process as gold plating and gold vermeil, the gold content and electroplating thickness are different. Chemical bonding helps to elevate your brand with gold filled jewelry, meeting the stipulated standard of at least 5% gold.

Process Explained

- Cleaning: The base metal should be thoroughly cleaned if not the gold filled jewelry will look uneven and smudged. Thus, it’s imperative that any dirt, oil, scratch, and other damages on the metal is cleaned.

- Immersion: The base metal is dipped into a gold ions solution according to the gold-filled thickness standard, which is created by combining positively charged ions of gold with an acid or a non-metal. After immersing the base metal into the gold ions solution, an electric current is applied to the solution, causing the gold ions to adhere tightly to the base metal.

Mechanical Bonding vs Chemical Bonding

Mechanical bonding limits the design possibilities, particularly for jewelry that has uneven, intricate or hollow surfaces. In addition, it doesn’t adhere to jewelry pieces with stones and irregular shapes since it can’t be bonded tightly and firmly. More importantly, it can be more expensive than chemical bonding.

Chemical bonding overcomes the limitations of mechanical bonding by ensuring the gold layer sticks securely, even on irregular and intricate surfaces. As a result, there’s no restriction to the type of custom gold filled jewelry that can be produced via this method. Also, the gold bonded is consistent and the process is fast, meaning that the whole pieces can be bonded fully with a consistent gold color and surface and bulk orders can be completed within a short period.

How to Identify and Test Gold Filled Jewelry

Discussed below are the ways to identify gold filled jewelry pieces and test their authenticity:

Stamps & Hallmarks

There are specific gold filled hallmarks and stamps to look out for when identifying high-quality gold filled jewelry. Check the inner linings of the jewelry to see the stamps and hallmarks. They include “GF”, “Gold Filled” or labeling of the gold content and finess such as 1/20 14K GF, meaning it is made with 14-karat gold and 1/20 gold (5% gold) of the total weight of the jewelry.

Electroplating Thickness Testing

One of the most accurate and reliable methods is through professional testing machines. The electroplating thickness testing method is used to verify if the gold filled jewelry meets the industry standard.

At Nendine, we offer a range of testing methods to ensure our jewelry meets the highest standards, such as electroplating thickness testing, with details results such as the composition of the metal used, the volume and weight of each gold layer, as well as the thickness of each layer. Send your jewelry sample to check if your gold filled jewelry meets the standard.

Key Takeaway

When comparing gold filled vs gold plating vs gold vermeil, gold filled is superior due to its bonding process and a thicker gold layer. If you want to explore how to incorporate gold filled jewelry into your branding and business growth, consult a reliable custom jewelry manufacturer.