Physical Vapor Deposition (PVD) coating has gained significant popularity in jewelry production because of its contribution to the durability and scratch resistance of jewelry pieces. However, it’s not suitable for all kinds of jewelry metals. Its application on soft metals like silver and brass often lead to so many problems, such as adhesion issues, shorter lifespan, unexpected costs, etc.

This comprehensive guide explores what is PVD coating on jewelry, how PVD vs electroplating compare, why PVD is not suitable for silver & brass jewelry, and what to use instead.

What is PVD Coating on Jewelry?

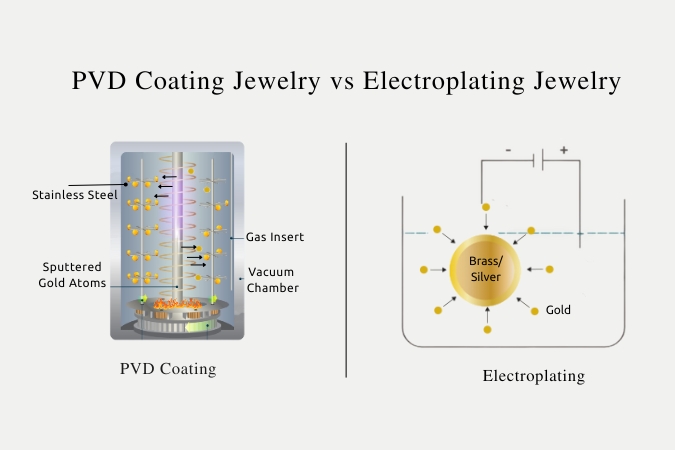

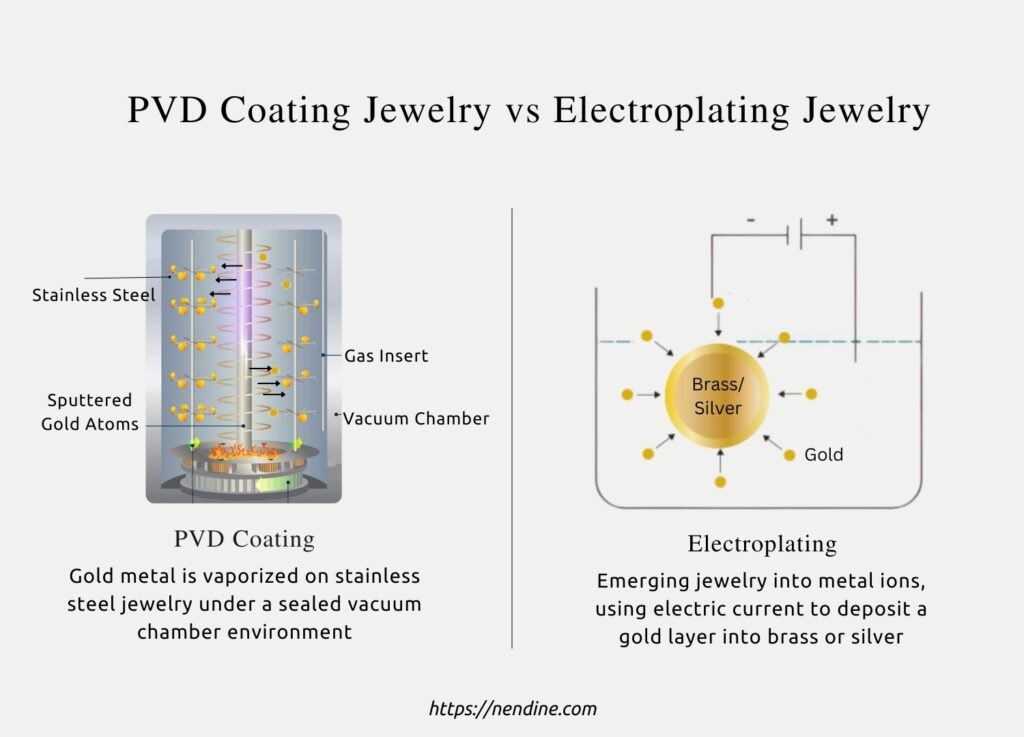

PVD coating on jewelry is an advanced coating technique that involves applying a thin layer of protective materials onto the surface of a jewelry using a vacuum chamber. PVD features a protective titanium nitride (TiN) layer between the stainless steel and colored metal surface. This is basically done to enhance the toughness and resistance of the jewelry against damaging elements.

Best Metal for PVD Coating & Why It Works

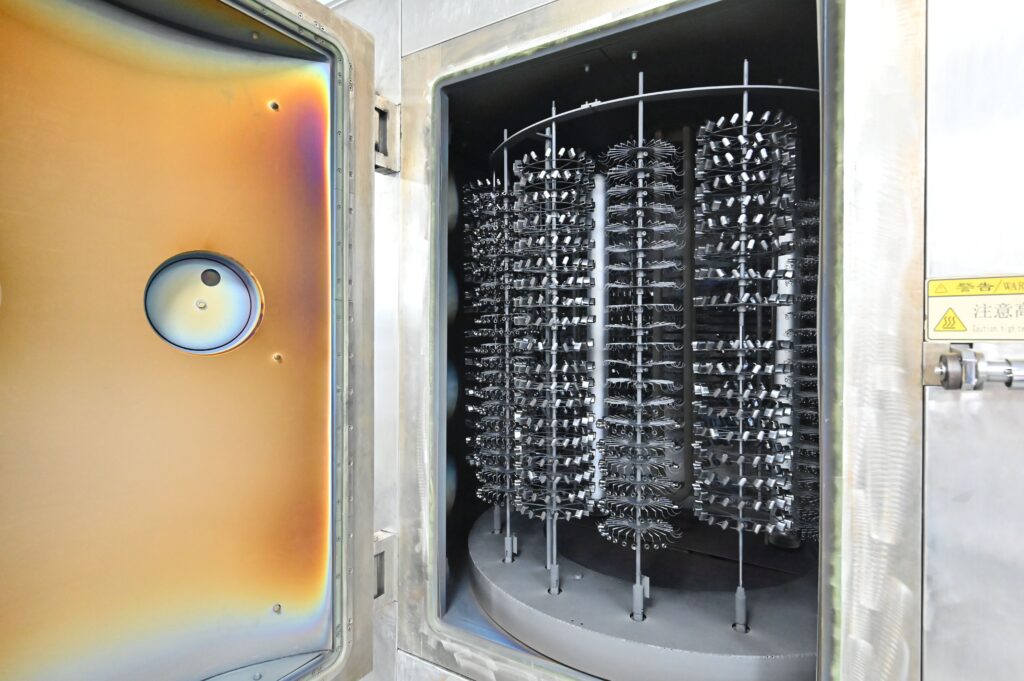

Stainless steel is the best metal for PVD coating. It is tough and its inherent hardness enhances the scratch resistance provided by PVD coating durability.

This metal offers a clean, stable, and non-reactive surface, allowing the PVD coating to bond strongly at the molecular level. This results in a uniform and durable finish that can withstand peeling or chipping.

Why Is PVD Coating NOT Suitable for Silver & Brass Jewelry?

Here are the major reasons why PVD coating on brass or PVD coating on silver jewelry are a big mistake:

- Low Melting Point and Risk of Deformation

Sterling silver jewelry and brass jewelry are made with soft metals, meaning that they can only be coated in a low-temperature environment. PVD, on the other hand, is a tough coating technique that’s done in a high-temperature vacuum environment.

Thus, using PVD technique on silver and brass jewelry can cause them to melt, deform, peel, and weaken their structural designs.

- Poor Adhesion between PVD Coating and Silver/Brass

Unlike stainless steel that has a rough composition that promotes coating adherence with PVD, silver and brass have a smooth, dense surface that’s unsuitable for PVD coating.

This surface incompatibility leads to weak bond between the silver/brass jewelry and the PVD coating, which is bound to result in peeling and flaking even under normal wear conditions.

- Tarnishing and Oxidation Affect Coating Quality

Silver easily tarnishes (forms silver sulfide) and brass oxidizes, which can darken the jewelry and negatively impact the performance of the PVD coating jewelry.

The tarnishing and oxidation continues under the PVD coatings, thereby creating internal stress and causing the coatings to crack.

- Complex and Costly Pre-Treatment Required

Achieving good PVD adhesion on silver and brass usually requires chemical pre-treatments and applying a layer of palladium before PVD. During this process, any slight error will lead to poor final plating results, making it more complicated, risky, and expensive.

This seems like a waste of resources, especially when you consider that it takes longer processing time while still not guaranteeing long-term coating performance.

Real-World Problems with PVD Coated Silver & Brass for Jewelry Brands

Using PVD coating or brass or silver jewelry creates some real-life problems for jewelry brands, such as:

- Flaking, Peeling, and Discoloration

Jewelry brands frequently get customer complaints about PVD-coated brass and silver jewelry showing visible discoloration and peeling within weeks of purchase. They begin to reveal the underlying metal, which can be very dangerous when they come in contact with the skin. Dermatologists have identified these improperly coated and cheap pieces as major causative factors for jewelry allergic reactions.

- The Hidden Costs Arise

The high scrap rate, the complex pre-treatment process, and the coating required before PVD increase the costs. If the coating fails, brands have to deal with more warranty claims, customer service issues, and product returns. They often have to choose between expensive re-coating processes or complete product replacement, both of which reduce their profit margin.

Better Solutions for Silver & Brass Jewelry

In cases like this where PVD is a bad idea for coating jewelry, there are usually alternatives. The best solutions for silver & brass jewelry are Electroplating and E-Coating.

- Electroplating (Water Plating)

Electroplating (also known as “water plating” or “aqua plating”) is an exceptional jewelry manufacturing process designed to match the inert properties of silver and brass.

The process typically involves inserting the jewelry pieces into an electrolyte solution that contains dissolved metal ions like gold. After that, a direct electrical current is passed through the solution to make the metal ions adhere tightly to the jewelry.

Electroplating is a low-temperature process, which means it can be used for silver and brass jewelry that have intricate designs. It efficiently coats delicate and detailed corners without compromising their shape or structure.

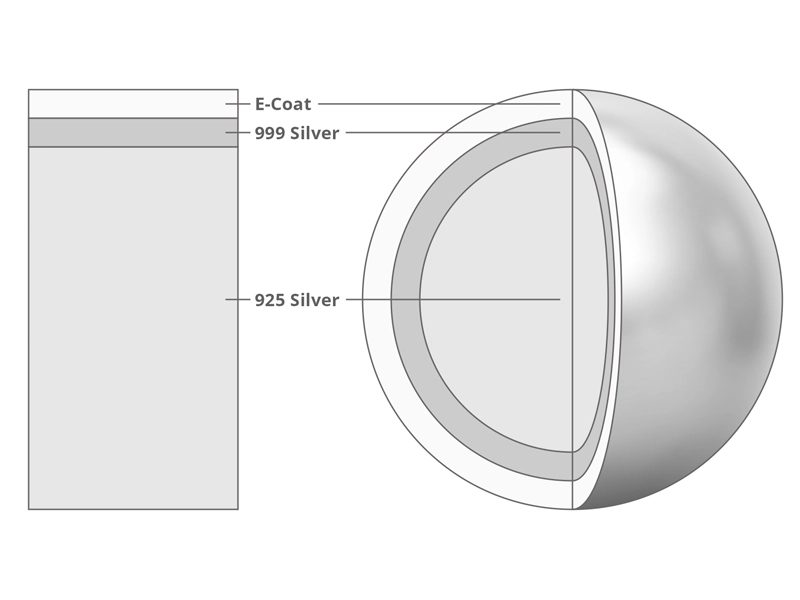

- E-Coating as a Protective Layer

E-coating is an additional protection that can be applied on silver and brass jewelry after electroplating to make them tougher and last longer. In Nendine, a protective layer of e-coating is often applied on electroplated pieces to strengthen their durability and color retention. Jewelry pieces that are e-coated can last 2-3 months longer than those without.

This protective layer is most valuable for brass jewelry, where it prevents the copper content from causing green skin discoloration while providing an ideal surface for final plating processes.

Comparison Table: PVD vs. Electroplating for Silver and Brass

This is a tabular representation of the PVD coating vs electroplating for silver and brass comparison. They are differentiated using crucial features that determine the overall quality of the jewelry pieces.

| Features | PVD Coating on Silver & Brass | Electroplating on Silver & Brass |

| Adhesion | Poor (high failure rate) | Good adhesion |

| Thermal Sensitivity | Risk of distortion | Low-temp process, safe for metals |

| Durability | Prone to peeling and tarnishing | Tarnish-resistant |

| Cost Effectiveness | May be expensive (a complex process) | Expensive but with great coating effects |

| Recommended Use | Not recommended | Yes |

Pro Tips on Gold Plated Jewelry for Jewelry Brands

To stand out among the multitude of jewelry brands on the market requires that you know a solid gold plating solution for jewelry collections. Here are some professional tips that can help:

- Match Plating Method to the Base Metal

Understand the best coating methods for each metal. For example, PVD is better for stainless steel while electroplating is best for silver & brass. This will improve the coating effects, durability, and prevent additional costs.

- Choose Electroplating for Color Customization

Gold PVD coating offers various colors like rose gold, white gold, and yellow gold, but electroplating does better by increasing how deep or light the gold color is. This allows you to have a distinct signature finish and respond quickly to fashion trends.

- Balance Coating Thickness and Flexibility

In PVD coatings on stainless steel, a thickness of about 0.03-0.08 microns offers superior durability and color retention. When it’s too thick, it can lead to peeling and discoloration. And for gold plating, the gold vermeil jewelry principle is advised—2.5 microns.

Conclusion

In this PVD coating vs electroplating guide, we’ve established that PVD is not the best option for silver and brass jewelry. Electroplating, on the other hand, is highly recommended for silver and brass jewelry because of its coating process and support of these metals’ inert properties.Above all, it’s important that you partner with a professional custom jewelry manufacturer to get the best option for your brand.

FAQs

PVD jewelry lifespan is usually determined by the coating quality, material used, and intensity of use. If all these factors are in check, then the jewelry can last for at least 2 years.

Some jewelry manufacturers use fake gold, which results in low-quality pieces that can cause skin reactions. But at Nendine, we use real gold to ensure your PVD coated jewelry lasts long and doesn’t affect your skin.

Gold PVD is highly tarnish-resistant, significantly more so than traditional gold plating. While not 100% immune to wear over many years or with harsh chemical exposure, it’s designed for long-lasting luster and can retain its color for 2 years.