MOQ (Minimum Order Quantity) is the number of items a manufacturer stipulates as the smallest amount you can order. Manufacturers often do this to accurately plan production, minimize waste, ensure optimal quality, and reduce overall costs.

MOQ in manufacturing jewelry is often high. Now, you might be wondering why is jewelry MOQ high?

In this article, we will explain the reasons why manufacturers usually set their custom jewelry MOQ to be high and how you can approach it even if your jewelry brand is just growing.

Understand Jewelry MOQ & Why It Is High

MOQs aren’t just random numbers that are casually decided. In the jewelry manufacturing process, MOQs are rules that influence the production of better, faster, and cheaper jewelry.

Below is jewelry MOQ explained in simpler terms and why it’s high:

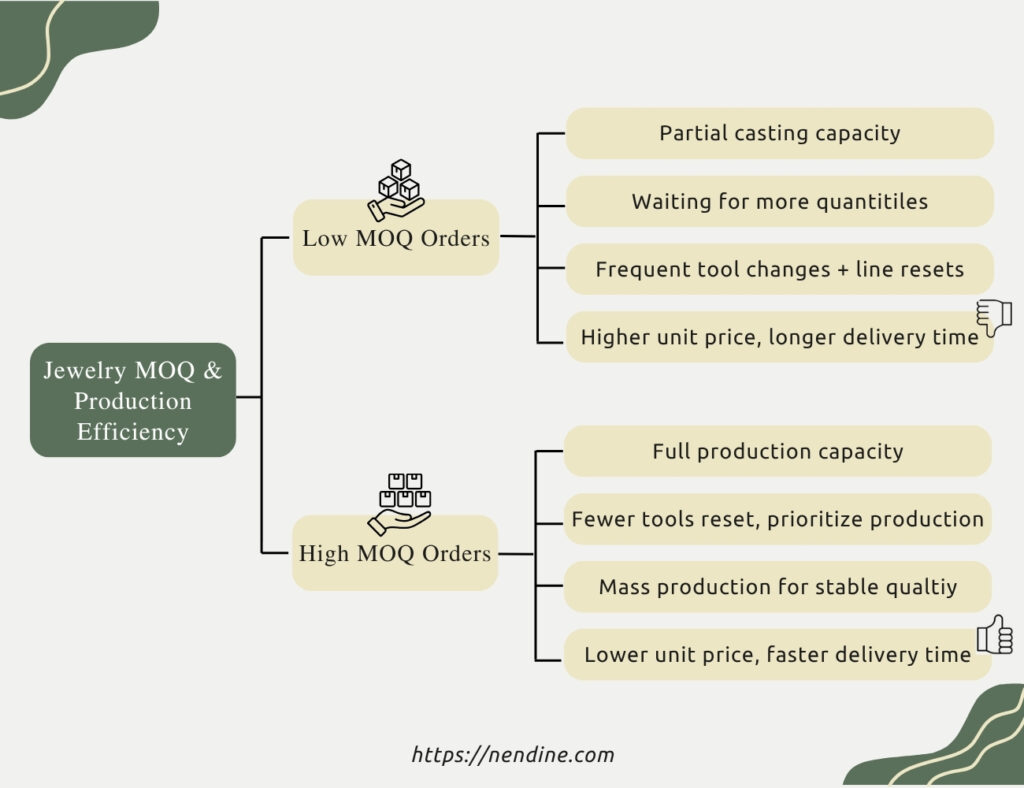

Ensuring Jewelry Production Efficiency & Quality Control

Setting high MOQs comes with having a ready-made plan to make jewelry production smooth and keep quality steady.

- Streamlined Production Improves Efficiency

Identical jewelry pieces are made the same way. High MOQ enables continuous production of a single style of jewelry without stopping to change tools or retrain workers. For example, if 500 pieces of sterling silver jewelry are needed, they can be made at a time, making production more seamless and fast.

- Quality Stability and Risk Reduction

When you try making a new jewelry, the first few trials may not be perfect, especially if they have complex designs or you’re using a new mold. But when you make a larger quantity at once, possible errors will be spread over all the jewelry, making them unnoticeable. Mass production enhances uniform quality control and reduces overall defects.

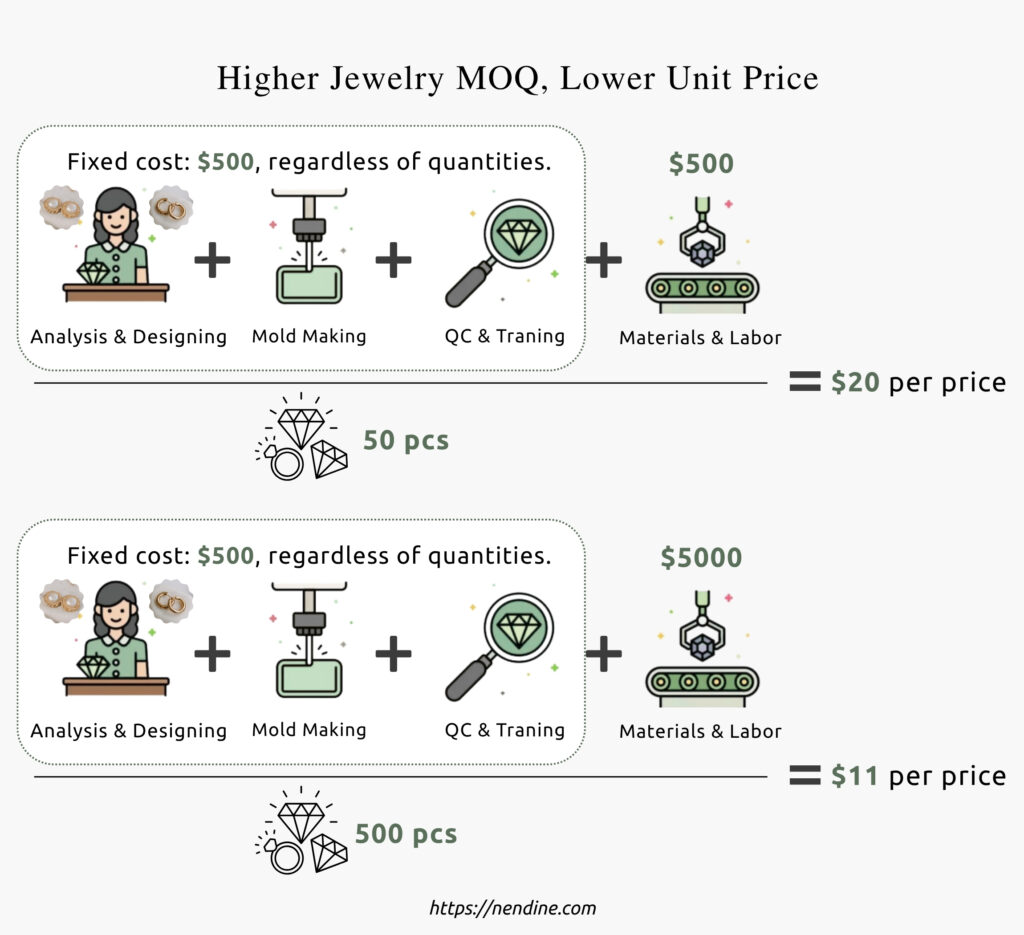

Optimizing Your Unit Cost & Guaranteeing Timely Delivery

Custom jewelry minimum order quantity lowers the price per piece and shortens the lead time.

- Spreading Fixed Costs to Lower Unit Price

Making jewelry can be expensive, as manufacturers calculate the costs of making the molds, designs, samples, and production setup. But if you order in large quantities, the costs can be spread, making each piece cheaper. Plus, manufacturers can buy raw materials and gemstones (precious and semi-precious) in bulk to get discounts. The larger the MOQ, the lower the jewelry price.

- Securing Production Priority & Rapid Turnaround

Just like other industries, customers who order in large quantities are treated as VIP and their orders are probably prioritized. For large order like private label jewelry large order, we assign a dedicated team to manage your project. This ensures personalized attention and smooth execution from start to finish.

Capturing the Market & Validating Your Vision

Custom jewelry MOQ helps you sell more, cut down hidden costs, and test the viability of your business ideas.

- Meeting Inventory Needs and Sales Targets

High MOQ ensures you have proper jewelry inventory management. You won’t experience shortage of products when there are sales opportunities (especially on major sales holidays like Valentine’s Day or Christmas Day). If you run out of products, you lose money and make your customers lose trust in you. Mass orders help you grab every sale!

- Streamlining Operations & Reducing Hidden Costs

Buying in small volumes all the time means constant communication with the factory, sample checks, shipping, and payment of fees. All these costs add up fast. High MOQ streamlines the procurement process and supply chain management. You order once and cut off subsequent expenses.

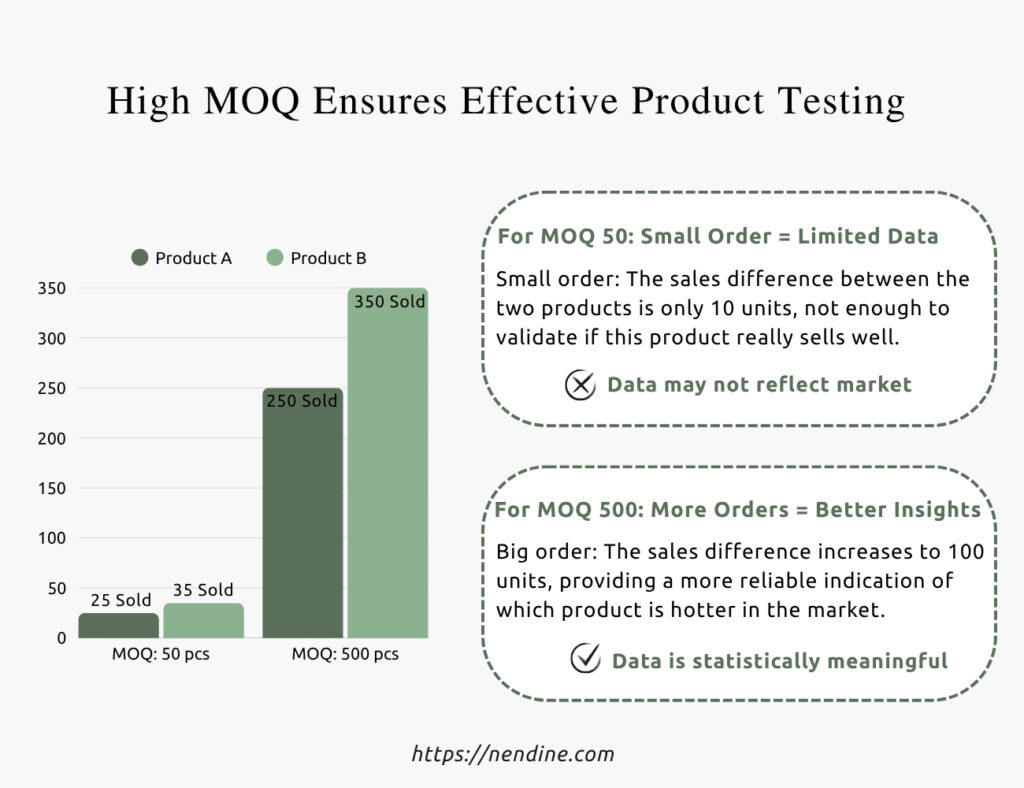

- Effective Product Testing with High MOQ

When you sell, you want to know what people love. Having products in large volume will let you know which style sells best and how fast it sells. The statistics from large MOQs provide a more reliable indication of whether the products truly sell best. This will help you make informed jewelry marketing strategies to improve your brand’s success.

MOQ Impact on Your Jewelry Business Operations

This table gives a side-by-side comparison of how your jewelry business will be impacted when you stick to Low MOQ or High MOQ:

| Operational Area | Impact of Low MOQ | Impact of High MOQ |

| Unit Cost | High | Low |

| Administrative Time | High (Repetitive tasks for each order) | Low (Streamlined, one-time process) |

| Delivery Speed | Often slower | Predictable & faster (Priority scheduling) |

| Inventory Risk | Risk of frequent stockouts | Risk of overstock if sales are slow |

| Market Testing Data | Less reliable, small sample size | More reliable, statistically significant data |

Actionable Insights for Jewelry Brands: How to Navigate MOQ Challenges

Even if your brand is in the early stages or prefers small batch sizes, there are smart ways to approach high MOQs without compromising your budget, quality, or growth strategy. They include:

- Choose from Mold-Ready or In-Stock Collections

An essential tip is to know how to find and choose the right jewelry manufacturer. Making new molds or jewelry can be expensive. So find a manufacturer that has quality pre-developed molds or in-house stock to avoid the high cost of making new molds or stocks.

This is a great idea if you’re testing new jewelry categories or want to get your products to customers fast.

- Launch with a Focused Capsule Collection

What affects MOQ in jewelry for growing brands is that they want to partake in all jewelry styles. Instead of selling different jewelry styles, focus on 3-5 super cool designs and order in larger volumes. This helps you meet the manufacturer’s MOQ requirement and get you the best jewelry styles in bulk. Don’t spread your budget thin across irrelevant products.

- Optimize Inventory through Data & Tiered Planning

Flexible MOQ for new businesses can be optimized through unbiased planning. Look at what sold well before or what’s trending. Use this to guess how much you will sell. Then, plan in layers: order in high volumes for your bestsellers, and order in smaller batches for new products. This way, you don’t waste money on items that might not sell.

- Batch Your Orders Strategically

Ordering small amounts every month is like going to the store every day for one apple—it’s a lot of work. This is to say, stop placing small reorders every month. Instead, plan quarterly orders (in larger volumes). You still get to sell monthly, but ordering them at once saves money on setup, shipping, and other overhead costs.

- Align Production Planning with Marketing & Sales Cycles

Don’t wait to contact your manufacturer when your sales campaign launches. Factories need time to make your jewelry and if you want faster delivery, the production cost will be increased because all workers will be diverted to your order. Plan ahead at least 3 months before and order in high volumes so you can launch with confidence and avoid “sold out messages” during peak seasons.

Conclusion

Again, why is jewelry MOQ high? It’s high to ensure production efficiency, quality, and cost savings. As a jewelry brand, you can navigate MOQs smartly, boost profits, and delight customers with stunning jewelry if you execute the actionable insights we’ve shared in this guide.

For more guidance, partner with a professional custom jewelry manufacturer to navigate MOQs and create sparkling jewelry designs to captivate customers.

FAQs

Yes, but reducing the MOQ can only be done in some conditions, depending on specificities of the order. If you have specific requirements, feel free to reach out.

Yes. At Nendine, we show you the price of each material, production, shipping, and other cost, to help you make an informed decision on your jewelry demands.