There are several techniques for enhancing the durability of jewelry. Amongst them are e-coating, electroplating, and enameling. But, e-coating stands out as an effective option for protecting your jewelry pieces, ensuring that they maintain their shine and color for a longer period.

Source: Pinterest

In this article, we will explain the peculiarities of e-coating jewelry, the process, the benefits, and things you need to know before choosing e-coating for your jewelry line.

What is E-coating on Jewelry?

E-coating on jewelry (also known as electro coating or electrodeposition) is a technique that uses electrical current to cover a jewelry surface with a lacquer. It involves submerging the jewelry into a ceramic solution and passing an electric current all over its surface to uniformly coat every part of the piece.

What Does E-coating Do?

Electro coating helps to create a thin layer of protection on a metal surface. It serves as a barrier that shields the underlying metal from elements that can cause oxidation or corrosion, such as moisture, air, and chemicals.

By extending the lifespan and aesthetic appeal of your jewelry, e-coating reduces the need for frequent cleaning and maintenance, making it a cost-effective option.

In addition to e-coating jewelry, this cutting-edge process is often used in various industries, such as the automotive, electronics, appliance, aerospace, marine, and construction industry.

Types of E-coating

E-coating is majorly splitted into two types, which are:

- Transparent E-coating

This is a clear, colorless type of e-coating. It protects the jewelry without influencing the natural appearance of the metal. Customers often prefer transparent e-coating on silver jewelry and gold jewelry because it shields the jewelry while allowing the underlying metal to shine brightly.

Source: Pinterest

- Colored E-coating

This involves coating jewelry pieces with unconventional colors like blue, pink, yellow, red, and orange. Colored e-coating allows you to change your jewelry surface to various popping colors without impacting the jewelry design. It can be used to create unique, fashionable pieces.

Source: Pinterest

How Does E-coating Differ from Enameling and Electroplating?

E-coating, enameling, and electroplating are 3 popular coating techniques. But how they differ from one another? The table below explains the respective differences.

| E-coating | Electroplating | Enameling | |

| Process | Submerging the jewelry into a ceramic solution and passing an electric current all over its surface to uniformly coat every part of the piece. | Depositing a thin metal layer onto a metal surface using an electric current. | A process by which powdered glass is fused to a metal substrate at high heat. |

| Appearance | Can be transparent or colored, glossy or matte, depending on the desired effect. | Metallic finish, shiny or matte depending on the metal used (gold, silver, copper). | Colorful and often glossy, with a smooth and glass-like finish. |

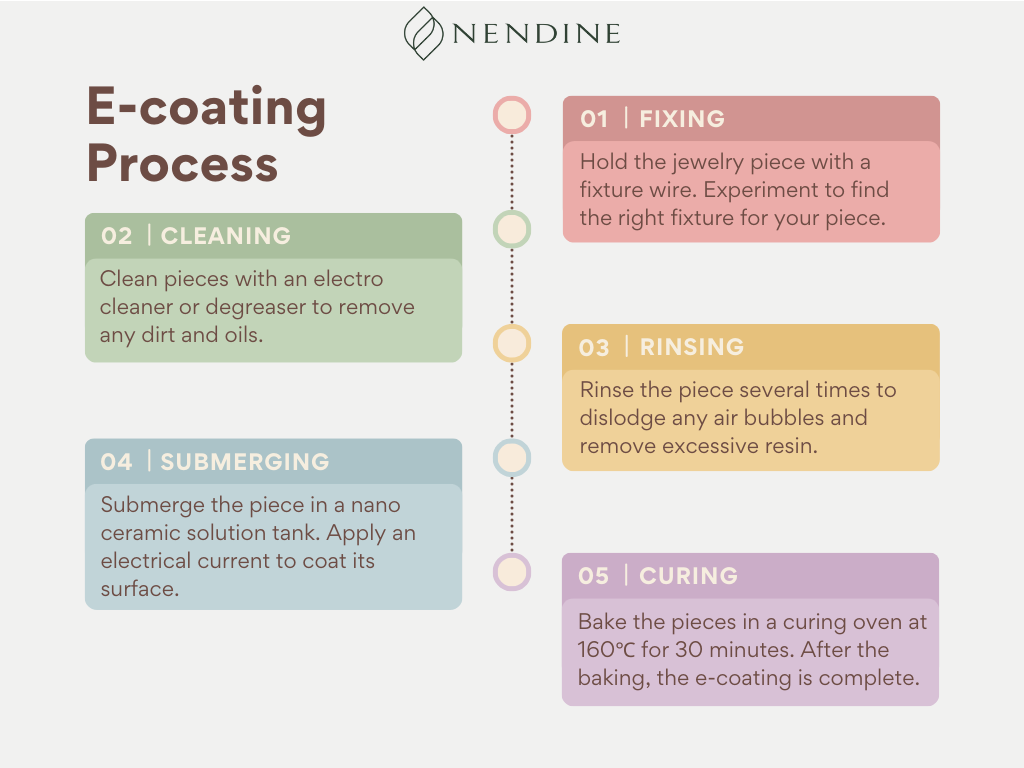

E-coating Jewelry Process

E-coating, a crucial step in jewelry manufacturing techniques, is applied as a final protective layer. Jewelry pieces need to go through polishing before electroplating. Following these, e-coating is applied in the final step. Let’s break down the e-coating process below:

Step 1: Fixing the Piece with a Wire

Begin the e-coating process for jewelry by securely attaching the piece to a fixture wire and test to determine the best fit. Ensure that no part of the jewelry is adhered to any other surface. For stacked pieces, repeat the process multiple times so that every part will be e-coated evenly.

Step 2: Cleaning the Jewelry

Clean the jewelry with an electro cleaner or a degreaser to remove any dirt, oil, or other contaminants that could interfere with the adhesion of the coating. Proper cleaning ensures that the e-coating process is successful and the coating adhering to the jewelry uniformly.

Step 3: Rinsing in Distilled & Running Water

Rinse the jewelry piece several times in distilled and running water to remove the cleaning agent and air bubbles attached to the jewelry. It’s important that the piece is rinsed properly after cleaning, as it removes excess resin from the surface of the jewelry.

Step 4: Submerging the Piece into the Ceramic Solution

Fully immerse the jewelry piece into a nano ceramic solution tank and pass an electrical current across to coat its surface. Ensure the entire jewelry piece is submerged in the solution and across its whole surface to get an even and consistent coating.

Step 5: Curing the Coated Pieces

Hang the jewelry to dry until it has a shiny and uniform coating appearance. Then, place the piece in a curing oven and bake it at 160⁰C for 30 minutes. This hardens the nano ceramic coating jewelry, making it durable and resistant to damaging elements.

Benefits of E-coating on Jewelry

- High Corrosion & Tarnishing Resistance

E-coating on jewelry involves infusing hybrid resin with a nano ceramic solution, which improves the jewelry durability against corrosion. It creates a protective layer that prevents the jewelry pieces from tarnishing, thereby ensuring they maintain their original luster and quality for a long time.

- Better Coverage of Hard-to-reach Areas

E-coating is efficient in producing uniform coating, which guarantees that all corners, including intricate parts of the jewelry are protected. This consistent and comprehensive coating enhances the overall strength of the jewelry.

- Eliminating the Orange Peel Effect

The “orange peel effect” refers to a textured, inconsistent finish that commonly found on large flat coated surfaces. This is visually unpleasant and can affect your jewelry’s beauty. E-coating jewelry minimizes this effect by providing a smooth and even finish.

- Various Colors and Finishes

E-coating jewelry is available in a wide range of colors and finishes, ranging from transparent to colored e-coating, as well as a lustrous or matte finish. The ability to choose different color options and finishes enables you to create custom pieces that suit your style.

Know These Before Choosing E-coating for Your Jewelry Line

E-coating is a great technique for improving your jewelry durability and prolonging the lifespan. However, the e-coating process is not ideal for all situations. Discussed below are crucial factors you need to evaluate before choosing e-coating for your jewelry line:

Source: Pinterest

- The Metal of Your Jewelry

The type of metal used in your jewelry production can influence the effectiveness and appearance of e-coating. It is important to consider the compatibility of the metal with the e-coating process before going forward.

For example, e-coating on brass jewelry, gold jewelry, and silver jewelry are perfect. But for products like stainless steel jewelry, it’s advisable to not use e-coating. Rather, go for PVD plating technique.

- Design Components

E-coating on jewelry is to enhance the piece design and not compromise its structural integrity or beauty. Thus, assess the design components on your jewelry to know if the e-coating process will accurately cover all the parts without affecting the overall appearance.

It’s a common misconception that stone and enamel designs cannot be e-coated, whereas these design components can be efficiently e-coated. Thus, make accurate findings about your design components before rushing to a conclusion.

- Desired Colors and Effects

The choice of colors and effects is an important factor because it is hard to remove or change. Whether you want a transparent, vibrant, or eye-catching color, e-coating can be used to achieve your desired result.

The versatility of e-coating allows you to experiment with various effects, shades, and finishes, enabling you to create multiple jewelry styles that appeal to different customers.

How Long Does E-coating Jewelry Last?

E-coating on jewelry adds extra lifespan to the normal duration of any jewelry. Under the right circumstances i.e., if the jewelry is under the same metal and if the e-coating process is properly followed, the e-coated jewelry will last for 2-3 months longer than other types of jewelry that are not e-coated.

Does E-coating Jewelry Tarnish?

E-coated jewelry pieces are highly tarnish-resistant. During the e-coating process, the pieces are infused with nano ceramic particles, making them resistant to abrasion, scratches, and other damaging elements.

Does E-coating Jewelry Wear Off?

E-coating is known for its outstanding durable finish that protects jewelry from tarnishing. However, the protective layer offered by e-coating is not forever. It will eventually wear off over time with continuous wear and tear.

Key Takeaway

E-coating on jewelry is exemplary of how your jewelry pieces should be if you want them to last long and continue to shine. It is boasted by protecting your jewelry from tarnishing and scratching, and offering customized and stunning jewelry pieces. To better achieve your desires, make sure you contact a sustainable jewelry manufacturer who is proficient in e-coating jewelry technique.